VAP® 3D ready-mades for large aerospace structures

VAP® 3D ready-mades developed and produced by Trans-Textil together with the Center for Lightweight Production at the German Aerospace Centre (DLR-ZLP) in Augsburg have again enabled the two partners to demonstrate the potential of prefabricated material kits adapted to component form. As part of the “Optimized vacuum bagging for CFRP rocket booster cases” project, DLR and Trans-Textil recently implemented the concept of instant-use multifunctional textile auxiliary packs in the case of a full-scale final-stage booster demonstrator measuring 3.4 metres in diameter and 6 metres in length for the Ariane 6 launcher.

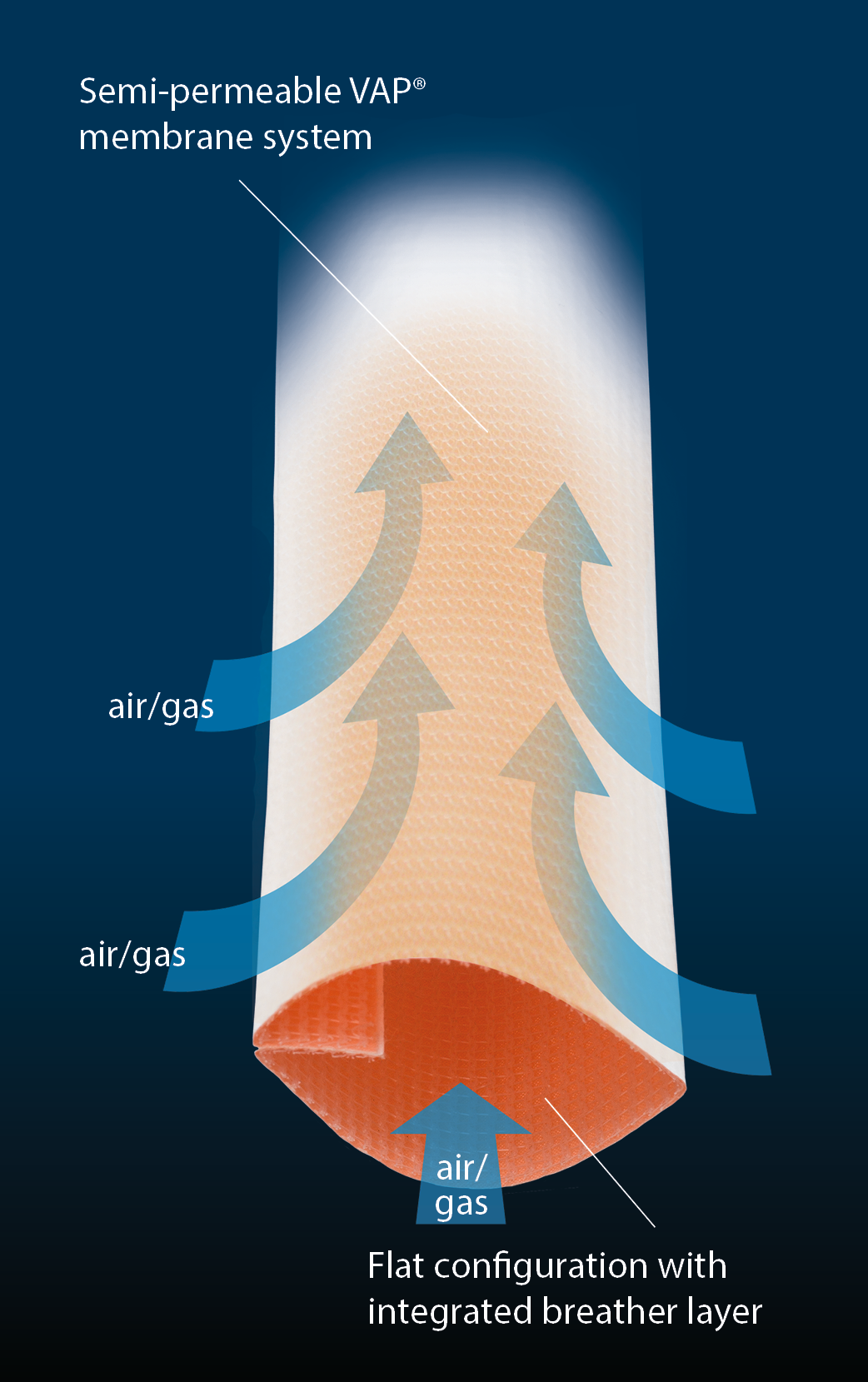

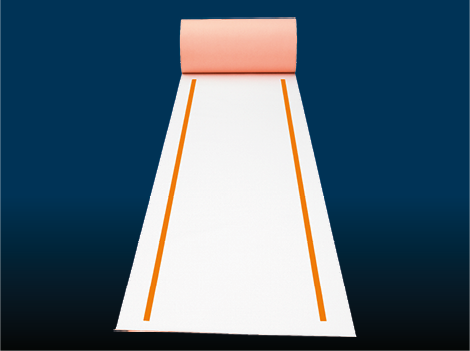

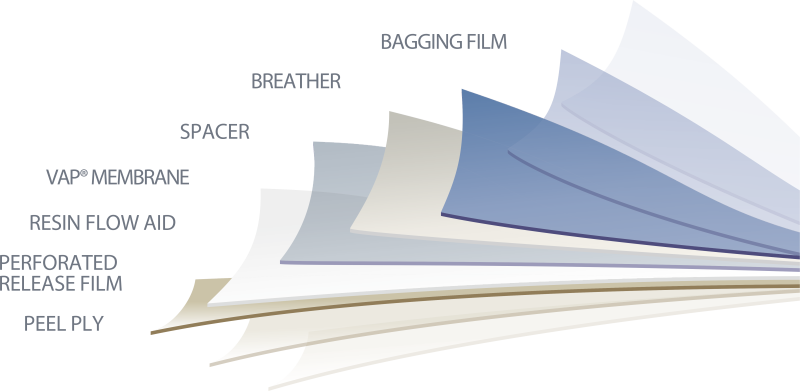

Special joining techniques made it possible to successfully adapt the central process component – digitally computed pattern pieces of the patented VAP® membrane system – to the complex component geometry with its cylindrical and curved sections while ensuring high accuracy of fit in the process. Thanks also to integrated resin feeds for out-of-autoclave infusion and an application-oriented packaging design, DLR and Trans-Textil have thus achieved the ideal prerequities for reproducible, simiplified and thus time-optimised deployment of fabrication incorporating VAP® 3D ready-mades.