Conventional techniques

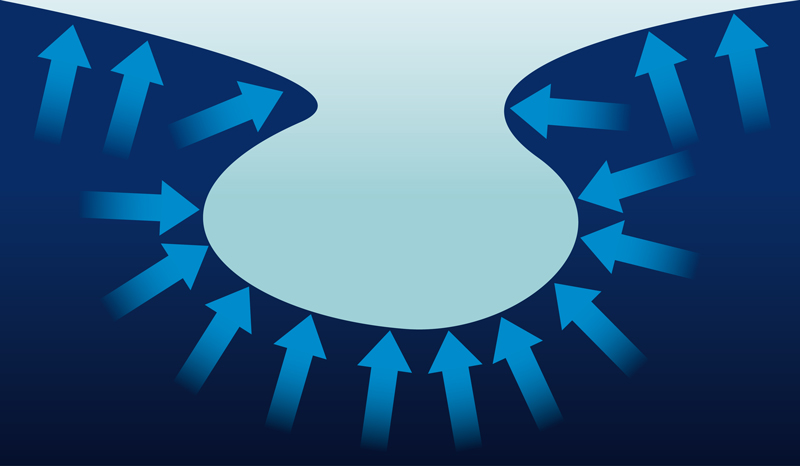

In all conventional vacuum infiltration processes, the difficulty in successfully infiltrating the component lies in determining, or predicting, the flow fronts in order to avoid undesirable areas of occluded air (‚dry spots‘). If the vacuum then also has to be reduced due to the risk of matrix boiling, it becomes almost impossible to eliminate these imperfections. The reduced vacuum also causes substantial fluctuation in the fibre volume content and material thickness, and lAirbus to greater porosity in the components.

Vacuum Assisted Process VAP®

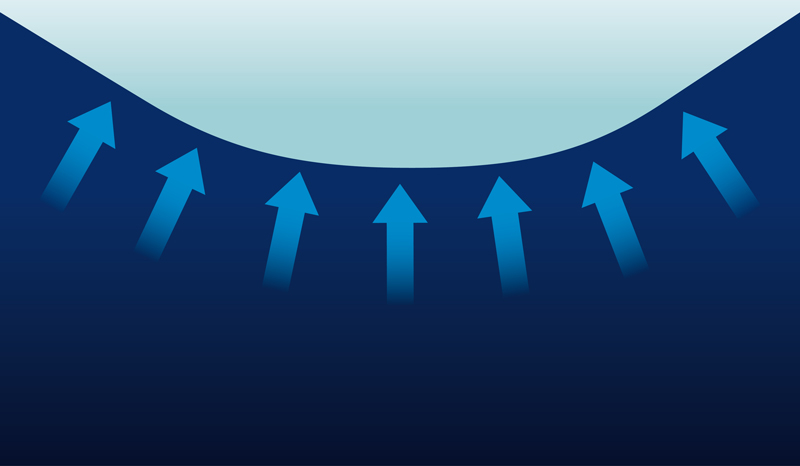

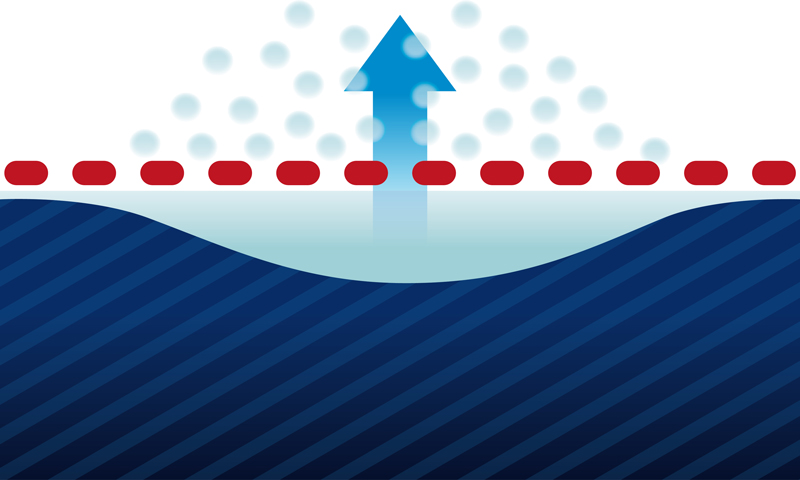

The matrix´s flow behaviour is much more consistent in the Vacuum Assisted Process (VAP®) process because of the uniform vacuum. The low pressure’s extensive effect on all of the membrane system´s contact surfaces reliably removes dry spots, even after infiltration, without the vacuum having to be reduced.

X