Functional textile solutions for VAP®

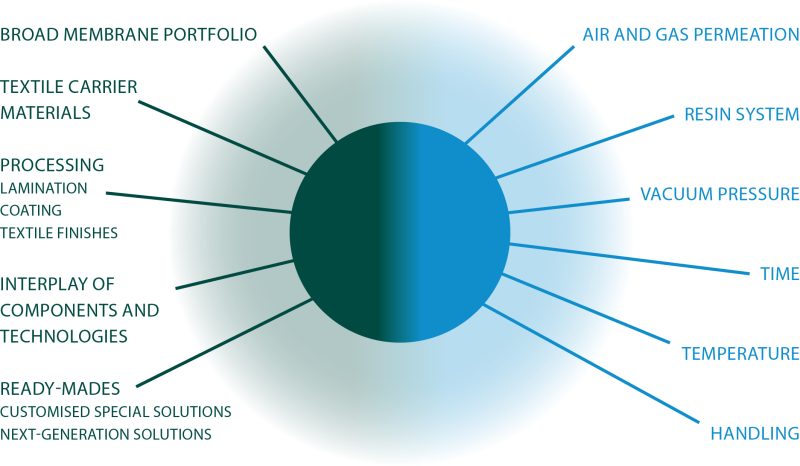

Trans-Textil’s work as a functional fabric specialist involves the development and production of sophisticated textile systems for use in VAP® membrane-assisted low pressure infiltration. Our VAP® membrane systems – the central component in the VAP® approach – are continuously adapted and optimized according to differing process variables and practical requirements, whereby our broad portfolio of semi-permeable barrier layers, the choice of a suitable textile carrier and precise production control enables us to develop flexible solutions tailored to the resin system and process variants involved. Along with adaptations according to specific requirements, these special solutions broaden the range of possible uses for our patented VAP® membrane systems still further.